Technologies for Skin Production

As part of the external page SKINTEGRITY Flagship Project of the University of Medicine Zurich, the Product Development Group Zurich aims to develop new technologies for the reproducible production of standardized skin equivalents for clinical and research applications.

Standardized Skin Models for Disease Research

Many studies have demonstrated the importance of considering the crosstalk between different cell types when studying the pathogenesis of complex multifactorial diseases such as scarring wounds, inflammatory skin diseases, and skin cancer. The successful investigation of such diseases therefore depends on reliable and standardized three-dimensional in vitro skin models. Effects such as cell-induced shrinkage or irregular thickness of skin models result in unpredictable variability between individual models that hinder the reliable evaluation of experiments.

The project is focusing on investigating novel technical solutions to improve current fabrication processes that increase the standardization and quality of in vitro skin models. Moreover, we work towards the automation of the fabrication process to enable a reproducible production of in vitro skin models on a large scale with the adjustability to specific experimental requirements.

The development of new technologies is conducted in close interdisciplinary collaborations with multiple research groups of ETH Zurich and University of Zurich.

Fabrication of Skin Grafts for Clinical Applications

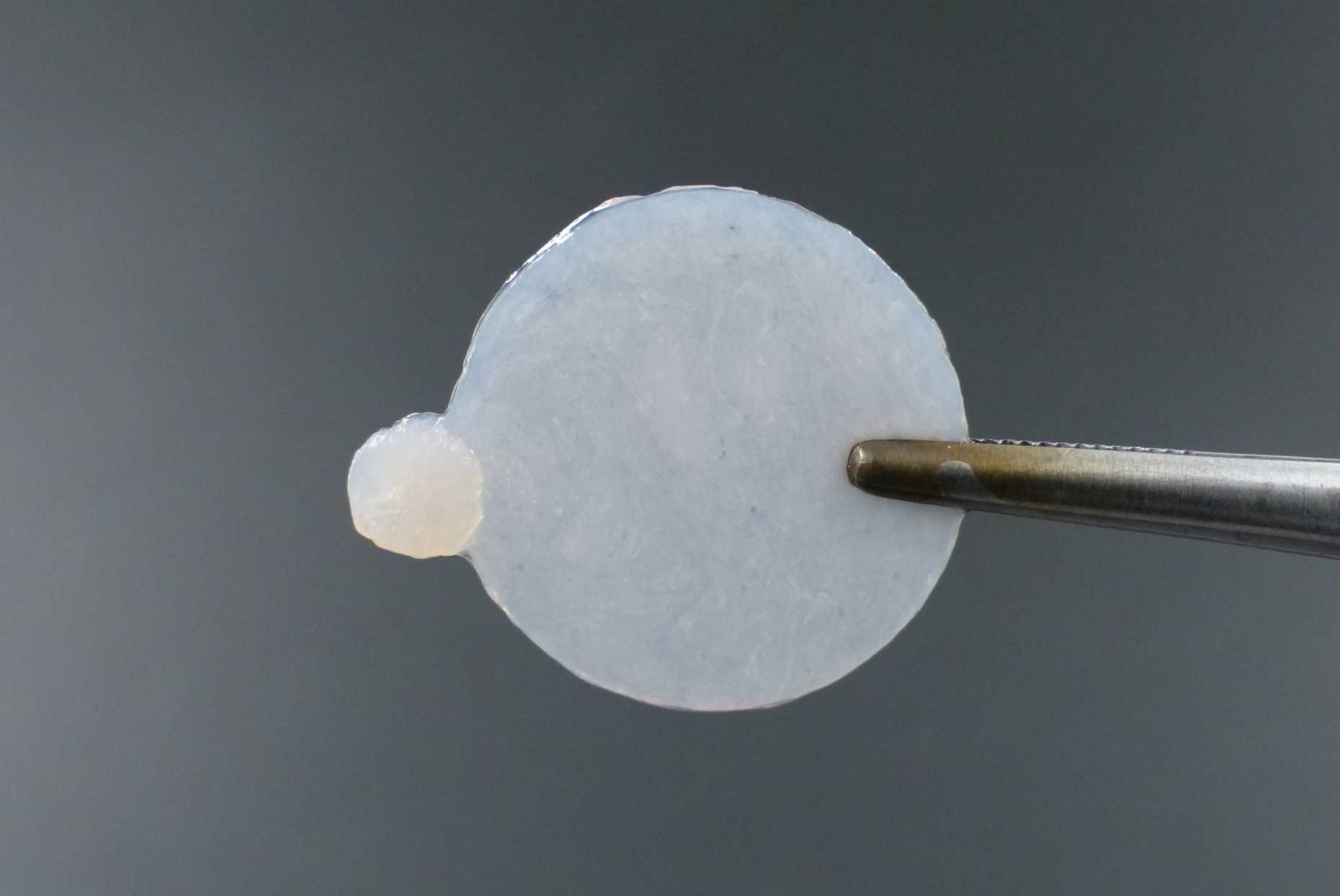

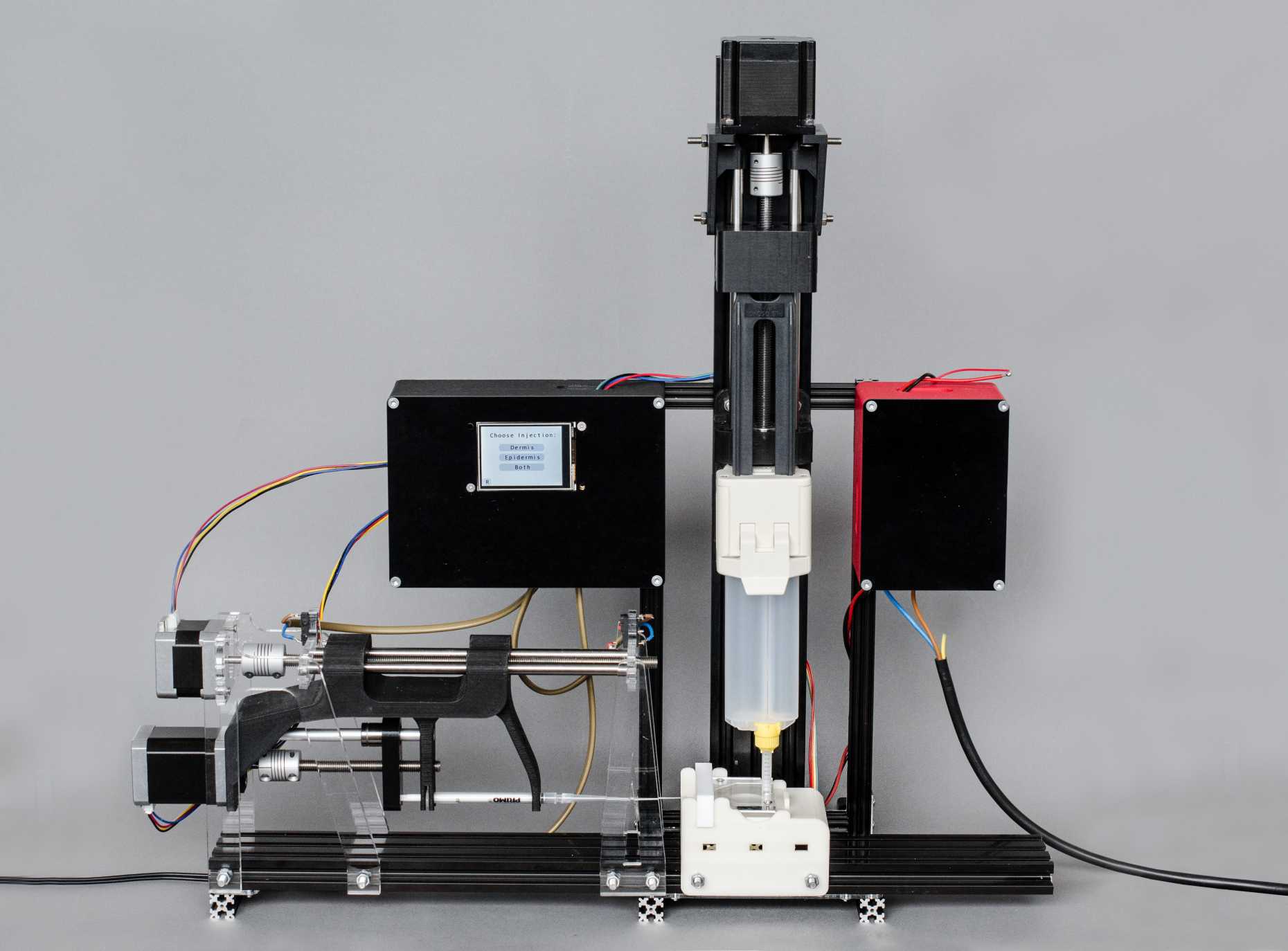

Novel clinical skin treatment methods are using skin biopsies of patients to produce personalized bioengineered skin graft. In contrary to conventional treatment methods for skin diseases, such as split-skin grafting or wound dressing, it can overcome the issues of undesirable scarring and movement restriction effects. Although the manual production is an established and clinically approved process, it still lacks in time and cost efficiency in order to be useful for large-scale application. Therefore, the Skin Creator project aims to develop a compact and robust fabrication system, which automatically produces skin grafts from biopsies. The project is focusing on analyzing current manufacturing process and adapting manual operated fabrication steps into automatable technologies. Through a close collaboration of biology and engineering, we can address biological questions through engineering solution providing inventions for future biological and medical research.

external page Rapid Graft: Project that is developping solutions to take small split-skin grafts to cover the demand of future trends in tissue engineering and gene therapy as well as to improve the treatment of chronic wound patients.