Silicone Additive Manufacturing for Biomedical Applications

A unique combination of properties makes silicone an attractive material for biomedical applications. Silicone has a high gas permeability, its shore hardness is tunable and silicone is bioinert. Since recently, complex silicone parts can be 3D-printed at ETH Zurich thanks to the Silicone Additive Manufacturing Platform (SAMP). Being a new process, its potential and limitations for biomedical applications remains to be explored.

For patients with critical lung failure, there remain only two options: lung transplantation or extra-corporal membrane oxygenation (ECMO). Donor lungs are scarce hence the waiting list is long, but current ECMO devices are not suited for long-term support. During ECMO treatment patients have to stay in the intensive care unit and are not mobile due to the cumbersome equipment. However, the development of improved oxygenators is inhibited by a limited understanding of the effect of flow path geometries and dynamic deformation of channels.

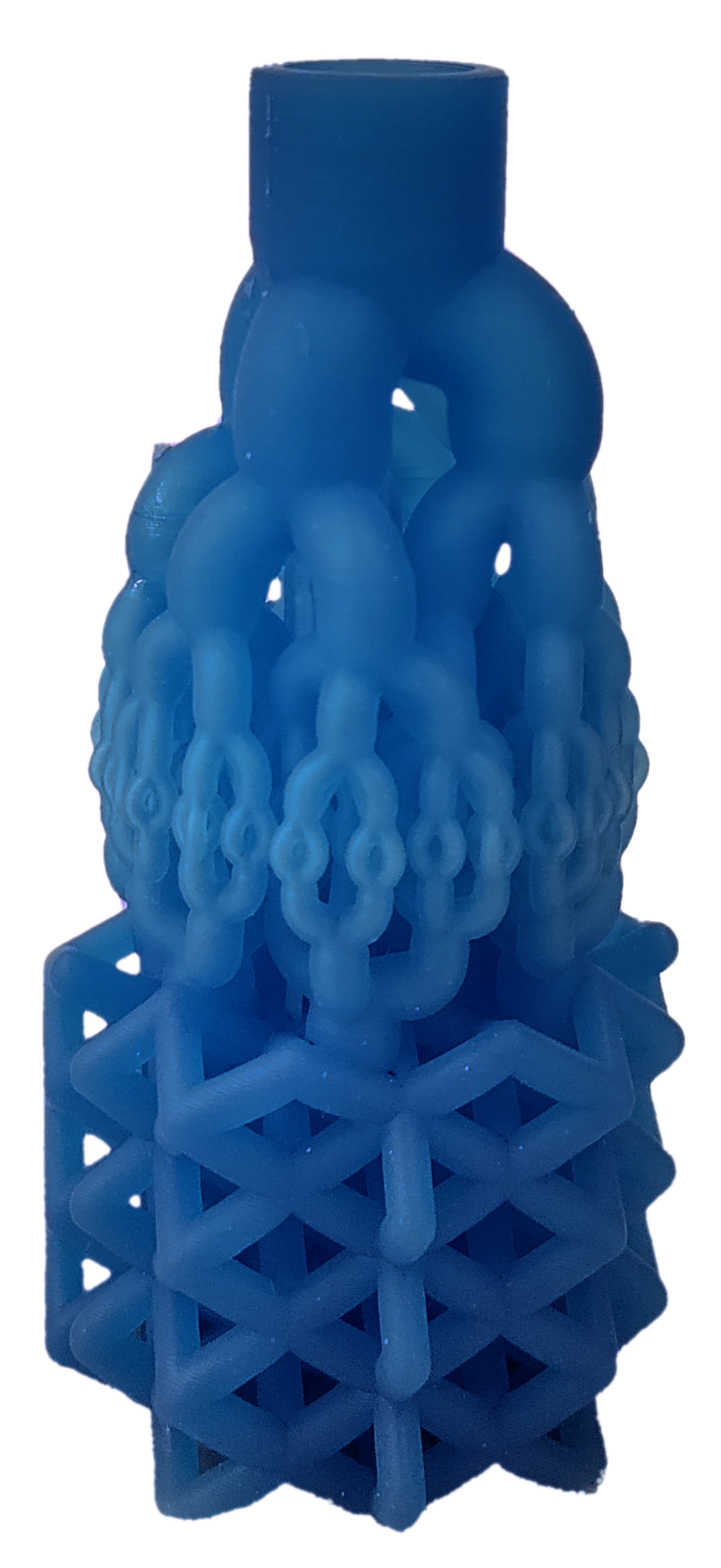

In recent years, it has become possible to additively manufacture (3D-print) silicone with high resolution. Additive manufacturing allows us to design complex flow paths to investigate the influence of blood compatibility and gas exchange performance. We can also use the flexibility of silicone to dynamically change channel structures.

In conclusion, we aim to contribute ways to improve hemocompatibility and gas exchange as well as to reduce pressure drop. All of this is needed to be able to miniaturize oxygenators enough to allow patients to be mobile and active.