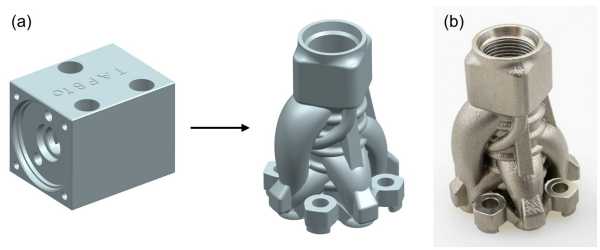

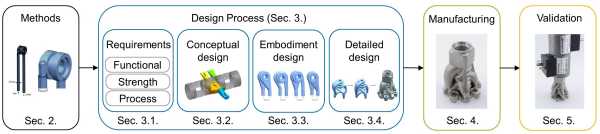

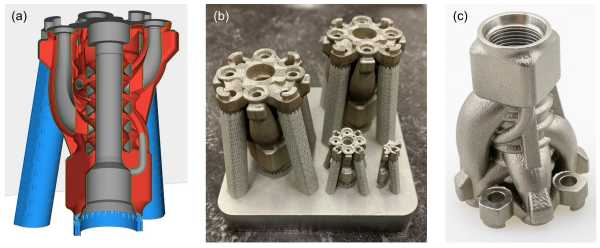

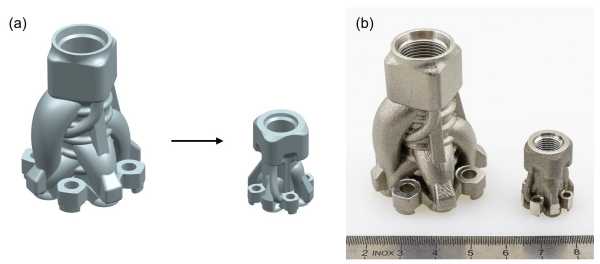

Together with external page Wandfluh and the external page FHNW, the p|dz and inspire have developed two sizes (NG3 and NG1.5) of an additively manufactured hydraulic spool valve in the framework of the Innosuisse project AMminiHyd. The results and learnings from this project are described in the published article "Design of an additively manufactured hydraulic directional spool valve: an industrial case study".

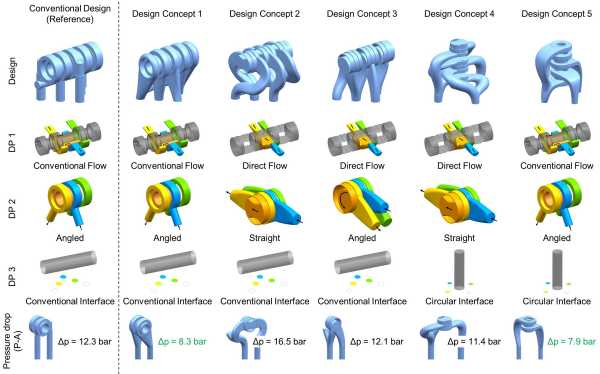

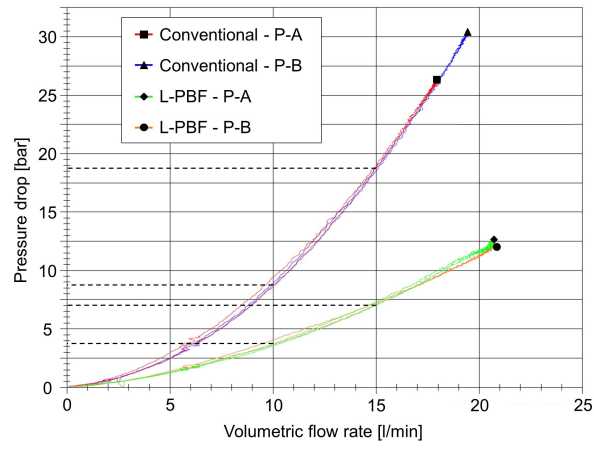

The case study demonstrates the benefits of the design freedom of the LPBF process for hydraulic components by achieving a pressure drop reduction of 60% and a weight reduction of 50%. The conceptual design phase, in which several design variants are considered, and the CFD simulation-based evaluation of these concepts, as well as the experimental validation of the final design, are emphasized. Finally, the potential of AM for scaling the generated designs with little additional design effort was demonstrated and discussed.