Design for AM Silicone Lungs

Silicone is already widely used in biomedical applications thanks to its outstanding properties. Now AM of silicone can achieve submillimeter details down to even single micrometer features. This offers great opportunities for biomedical applications with complex internal structures such as bioreactors or oxygenators.

Oxygen permeability of AM silicone

In our research we studied the oxygen permeability of additively manufactured silicone membranes made from TrueSil (SpectroPlast AG). Measurements were performed with two membrane thicknesses (0.5 and 0.8 mm) and four different Shore hardnesses (20A, 35A, 50A, and 60A) at 15, 20, and 25°C. We found that the oxygen permeability decreased with increasing Shore hardness. TrueSil 20A was comparable to ELASTOSIL® Film (Wacker Chemie AG) in terms of oxygen permeability. Membrane thickness did not affect permeability, but the Shore hardness affected the thickness. Membranes with Shore hardness 20A or 35A were manufactured over 0.1 mm thicker than designed, while the others deviated less than 0.04 mm.

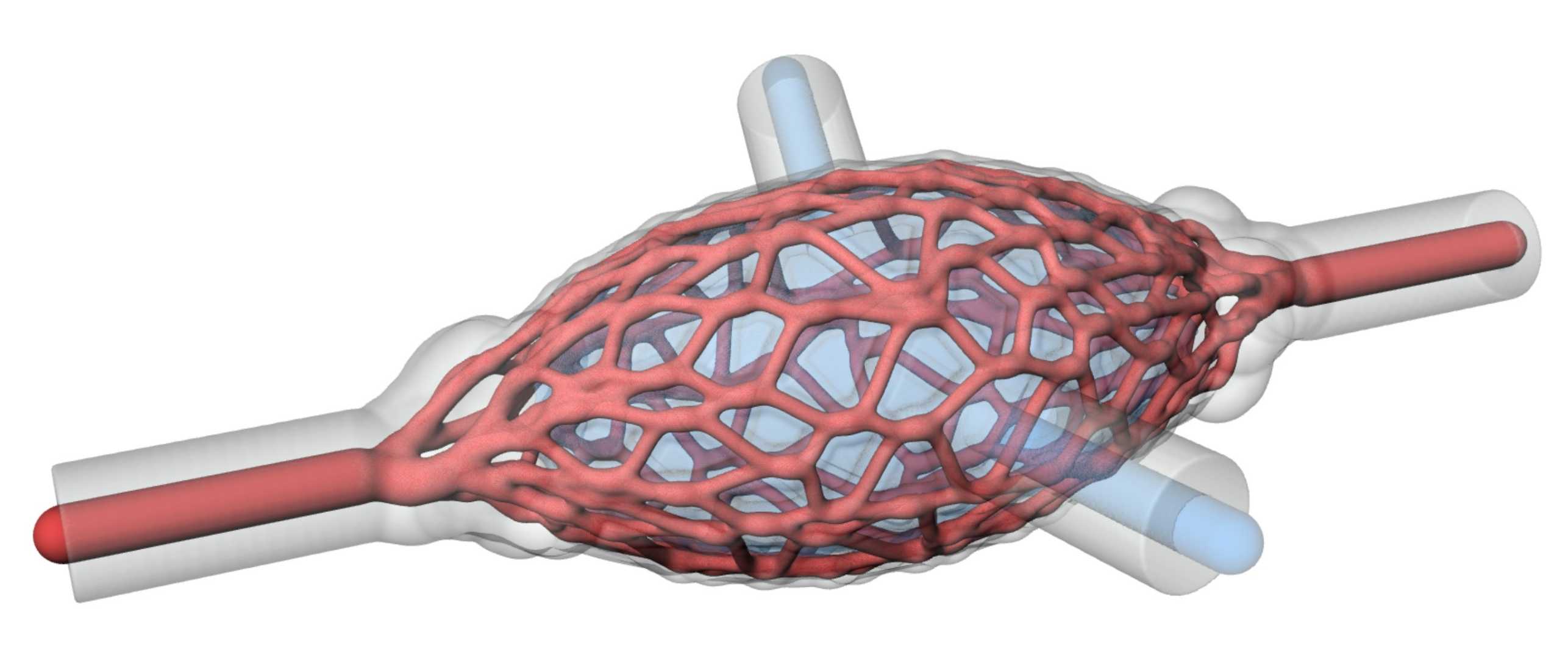

Silicone Additive Manufacturing of Artificial Lungs

The vision is a mini extra-corporal membrane oxygenator (ECMO) for outpatient use. With Silicone Additive Manufacturing (SAM) now available, the objective is to evaluate the feasibility of SAM artificial lungs (AL) and how the blood flow path should be designed for SAM. Inferior silicone hemocompatibility favored other materials to be used in ECMO systems, but silicone remains a great platform to study optimized additively manufactured artificial lung designs. Further, knowledge gained with SAM could be later transferred to newly developed materials.

The oxygenation, CO2 removal efficacy, pressure drop, and haemolysis of three silicone concepts were evaluated.

For more information please contact Marcel Gort or Julian Ferchow.