Additive Manufacturing for Structural Components in Superconducting Coils

AM Structures for Superconducting Coils - CHART MagAM

Nb3Sn-based coils of superconducting accelerator magnets are impregnated together with their structural components (wedges, endspacers, winding formers etc.). The adhesion between the impregnated winding and the structural parts is a potential weak point, often linked to excessive training of Nb3Sn magnets.

Additive Manufacturing (AM) has the potential to produce very complex structures such as the winding formers of canted-cosine-theta coils (CCT), while adding enhanced functionality for increased adhesion, thus contributing to improved magnet performance. This project intends to bring these potential benefits into superconducting accelerator magnets.

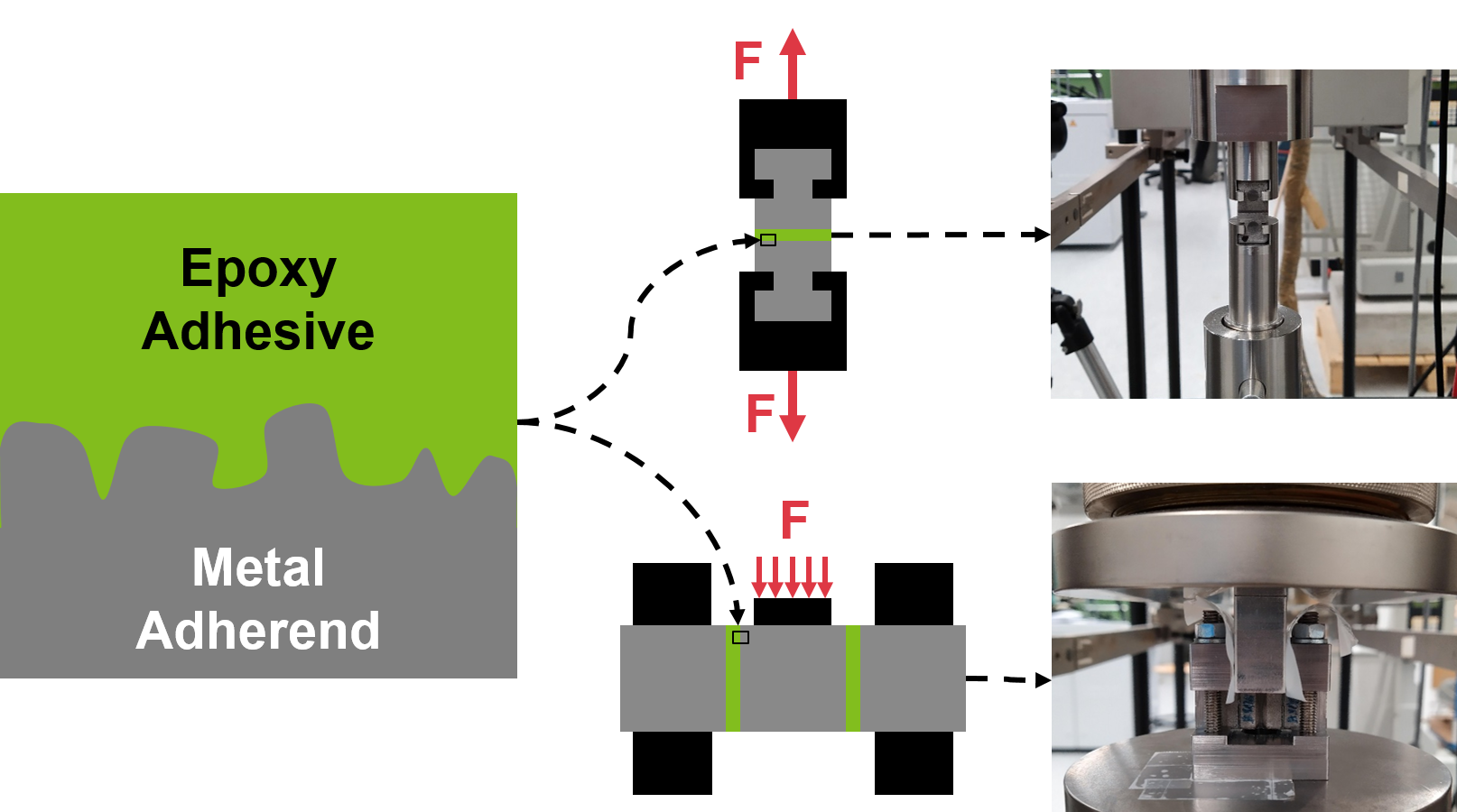

To test different surface structures for improved adhesive joints, an epoxy casting process is developed and samples are tested under shear and tension loads. Since superconducting magnets are operating at cryogenic temperatures, these tests are performed at room temperature and in liquid nitrogen (LN2).

This project is part of the CHART initiative for particle accelerator research and technology in Switzerland: external page www.chart.ch

For more information please contact Patrick Beutler or Julian Ferchow.